With step-by-step calculation instructions

When selecting repair products for their utility, price is first and foremost in the minds of procurement managers. While this is an important consideration, the time, effort and labor involved to install the repair product, or installation cost, can make a bigger impact on a utility’s bottom line compared to price alone. Labor costs are the largest expense for any utility so reducing the amount of time to install the product can make a substantial difference as utilities look to maximize their resources against limited budgets.

We have developed a total cost of installation calculator that makes it easy to compare products’ installation cost to provide a fuller and more complete cost assessment for pipe repair installations. This includes the product price and also takes into account the:

- Number of workers performing the installation

- Hourly wages for each worker in the crew

- Total installation time

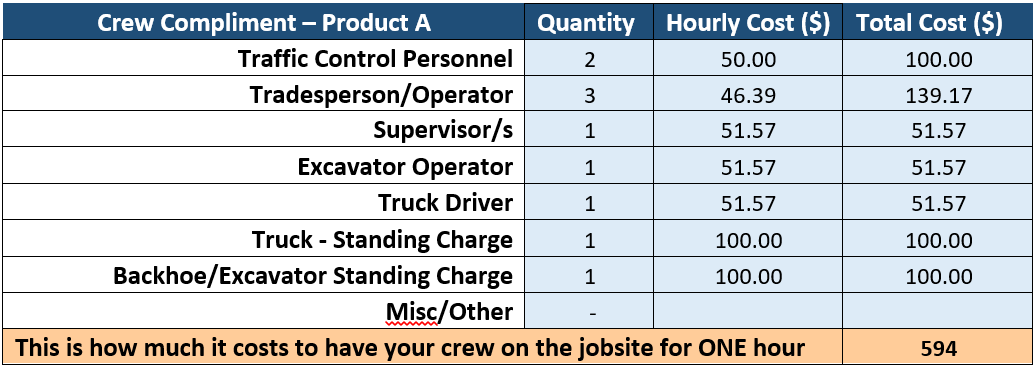

STEP 1 – Calculating Crew Costs

See below an installation cost calculator with each worker involved and their hourly wage to obtain an hourly cost of labor.

In this example, the hourly labor cost for the crew is $594 (see last line of the table).

Once an hourly labor cost is determined, the calculator can automatically compute the total cost of installation if you know approximately how much time is spent installing a particular product, including excavation, placing the product onto the pipe, and installing any restraint systems if necessary. The calculator can then compare the total installation cost against any HYMAX product which is based on HYMAX’s estimations obtained over years of observing their product installations.

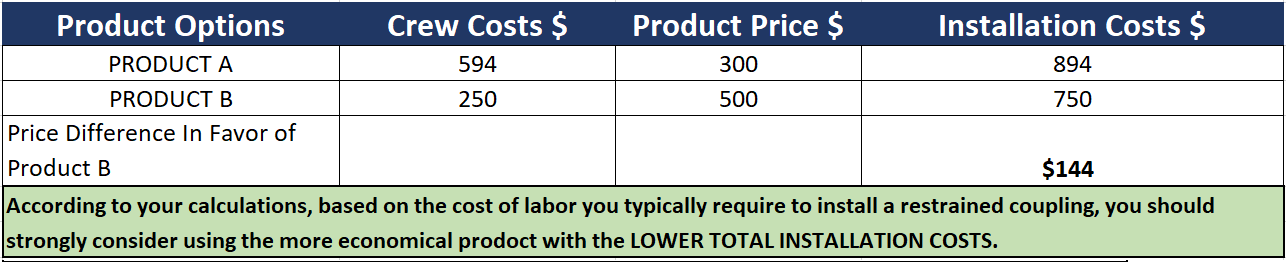

STEP 2 – Calculating Total Installation Costs

Use hourly crew costs and all other installation costs to compute the accumulative TOTAL INSTALLATION COST.

See below a sample calculation of TOTAL product and labor costs using PRODUCT A vs. PRODUCT B.

While comparing product price is simple to assess, it doesn’t provide a full picture of all the installation costs involved. Products’ cost effectiveness varies according to the time needed to install the product as well as to other factors:

- # of bolts to close

- Under-digging needed

- Easier access to Top-facing bolts

- Mono block or assembly needed

- # of workers needed

- Added equipment / other resources

- Long-term installation durability due to material anti-corrosion qualities, dynamic deflection absorption etc.

By examining total installation costs, utilities can gain a better appreciation of the true cost of the repair and make better repair product choices. Although the product itself may be more expensive, its total installation costs may be lower than the alternative.

To receive a demonstration of the total installation cost calculator with your own repair products, contact us by clicking this link.

Leave a Comment: